Thermo-Loc Frustrations? Here’s What Might Be Going Wrong and How to Avoid it

When working on delicate engraving, stone setting, or jewelry repairs, securing your workpiece is crucial. Traditional vises and clamps may not always provide the flexibility needed for intricate work, especially with irregularly shaped or fragile objects. That’s where Thermo-Loc comes in—a heat-activated, reusable fixturing material designed to provide a firm, non-marring grip for precision work.

In this guide, we’ll cover:

- What is it and how it works

- Common problems and how to avoid them

- How to use it effectively

- General applications and alternative materials

What is It?

Thermo-Loc is a moldable, heat-activated plastic compound used for securely holding workpieces in place during engraving, jewelry making, gunsmithing, and other precision tasks. When heated, it softens and can be shaped around an object or fixture. As it cools, it hardens to create a vibration-free, secure hold.

Why Thermo-Loc?

- Heat-Activated & Reusable – Softens with heat and hardens when cooled, making it easy to reshape and reuse multiple times.

- Strong but Non-Marring – Provides a firm grip without scratching delicate surfaces.

- Customizable Fit – Molds around irregular shapes for a secure hold.

- Minimal Residue & Non-Toxic – Leaves no sticky film and is safe to use in any workshop.

- Vibration-Free Stability – Reduces movement for cleaner engraving and precise detailing.

Troubleshooting Thermo-Loc: Common Challenges and Solutions

While Thermo-Loc is a reliable and versatile workholding material, users may occasionally encounter a few challenges. Just like with most things preparation is the key to avoiding issues down the road. Below are some of the most frequent issues and practical solutions to help ensure a smooth experience.

1. Stuck in small holes or grooves

Pro Tip: Use either thin plastic or tape to seal off any small holes or groves to prevent thermo-loc from getting into those small spaces

2. Residue or Marks on Workpieces

Although Thermo-Loc is designed to be non-marring, some materials—such as polished metals or gemstones—may retain slight marks from direct contact.

Pro Tip: Place a thin protective layer (such as plastic wrap or wax paper) between Thermo-Loc and your workpiece before molding.

3. Sticking to Hands or Workpieces

Overheating Thermo-Loc can make it too sticky, which may cause it to cling to your hands or leave unwanted residue on your workpiece.

Pro Tip: Let it cool for a few seconds before molding, or wet your hands slightly to prevent sticking.

4. Becoming Too Brittle or Cracking

If cooled too quickly, especially with compressed air, Thermo-Loc may harden unevenly and become brittle, leading to cracks.

Pro Tip: Allow it to cool gradually at room temperature for a more durable hold.

5. Difficulty in Softening the Material

If Thermo-Loc is not heated sufficiently, it remains too stiff to mold properly, making it difficult to secure your workpiece.

Pro Tip: Ensure your water is heated to 150-160°F (65-70°C) or use a heat gun for more controlled and even softening.

By understanding these potential challenges and their solutions, you can maximize the effectiveness of Thermo-Loc in your engraving, jewelry, or precision work. With the right techniques, it becomes an indispensable tool for secure and reliable workholding.

How to Use Thermo-Loc: A Step-by-Step Guide

- Heat the Thermo-Loc

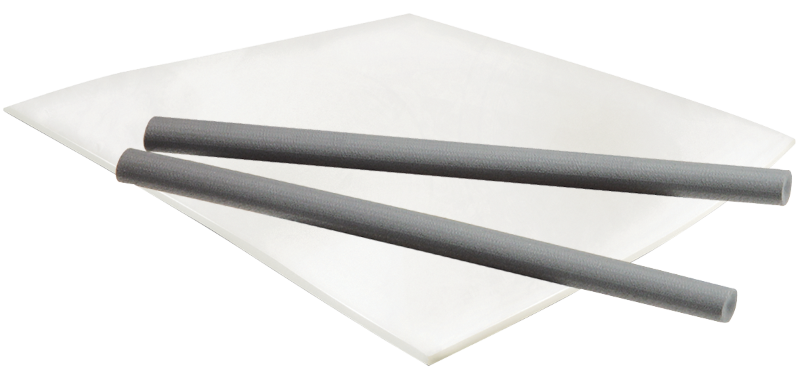

- Place the sticks on the PTFE pad and place them in microwave heating in 30-second intervals until pliable. Other options include placing them in hot water (150-160°F / 65-70°C) for a few minutes or using a heat gun.

- The material should become soft and pliable.

- Mold the Material Around Your Workpiece

- Shape the softened Thermo-Loc around the object or press it into a fixture.

- Ensure even coverage to prevent movement while working.

- Let It Cool & Harden

- In a few minutes, it will solidify, locking the piece in place.

- Speed up the process with compressed air or a fan if needed.

- Work on Your Piece

- Engrave, set stones, or perform other detailed tasks with enhanced stability.

- Remove & Reuse

- Reheat to soften, remove the workpiece, reshape the material, and store for future use.

Check out this video for more information about how to best use Thermo-loc

General Applications

Engraving – Holds rings, firearms, knives, and jewelry for precise detailing.

Stone Setting – Keeps rings and pendants steady while setting gemstones.

Jewelry Repair – Secures delicate items during soldering or repairs.

Gunsmithing – Provides a stable grip for engraving firearm components.

Watchmaking – Stabilizes watch cases and components for precision work.

Reliable Alternatives

While Thermo-Loc is an excellent choice, other materials may suit different needs:

- Shellac Sticks – A traditional jeweler’s option that requires an alcohol lamp but can leave residue.

- Engraver’s Cement (Pitch) – Used for traditional hand engraving and stone-setting but can be messier.

- Leather or Rubber Jaw Pads – Ideal for larger, flat surfaces but lack custom molding capabilities.

Final Thoughts

For engravers, jewelers, and craftsmen, Thermo-Loc is an essential workholding solution that offers a strong, reusable, and non-marring grip. Its ability to mold around irregular shapes, provide vibration-free stability, and be used repeatedly makes it a top choice for professionals. By putting in just a few minutes of prep time before use you can avoid almost all of the common challenges.

Ready to take your workholding to the next level? Work smarter not harder with GRS tools and Training.